State of the art: Good-bye, charging cable

Is this the future? Constant fiddling with a charging cable that can sometimes be rolled up a bit stubbornly and is dirty after a short time? The future has more solutions in store, and we don't have to wait longer than three or four years for them. At the forefront: inductive, contactless charging, which we have known for some time from mobile phones (and not only from it). There is also conductive charging, also known as wired charging. With this technology, the fixed electrical connection between the car and the power grid is established automatically by a small robotic arm. Inductive and conductive charging are already being tested and will soon be ready for series production. We explain here what distinguishes them and where they differ.

Charging by induction – the toothbrush has been able to do it for decades

For electricity to flow, there does not necessarily have to be a cable. At least apart from the cable that connects the charging station to the power grid. However, there is no cable connection from the e-car to the charging station if inductive charging is used. The car only has to park above the power-supplying station. It contains a coil through which alternating current flows. This current generates a magnetic field. In the receiver part of the electric car under the nose, there is also a coil that uses induction. Induction means that a changing magnetic field generates electric current in a neighboring piece of metal. There is always a small gap or air gap between the coils. In the case of electric toothbrushes or mobile phones, which have been able to be charged inductively for a long time, the gap is only a few millimeters in size, while in the case of an electric car it can be 15 to 20 centimeters wide. The rule is: the narrower, the better, for efficiency.

Systems that enable inductive charging of our electric cars have long since left the test laboratories and are now being tested under real conditions. "Halo" is the name of the American manufacturer WiTricity's inductive charging system. It is designed in such a way that it can be installed directly in the series production of a car or retrofitted. In Germany, the Americans have won the company ABT e-Line as a partner for such retrofit solutions. Normally, "Halo" is supposed to charge with eleven kW and achieve an efficiency of 92 percent in power transmission. According to WiTricity, inductive charging would be as effective as tapping power via cable. By comparison, we achieve a slightly higher efficiency of about 94 to 98 percent with the cable; the rest, mostly as heat generation, is lost during charging. BMW is convinced that charging is even easier than refueling. The BMW Wireless Charging option can be ordered for the 530e iPerformance, for example.

Inductive charging systems are convenient and robust

One of the advantages of wireless charging is its insensitivity to dirt. The electromagnetic waves penetrate everything that is not made of metal. The system also works on snow, mud, dust, ice, water, leaves and all non-metallic debris that is under the car between the charger and receiver. Since there are no moving parts, it is more robust, reliable and convenient than any other charging system.

However, there is still a lack of standards that describe the system precisely and define its technical content so that it can be used internationally across manufacturers. However, various organizations (SAE, ISO, IEC, SAC) in the USA, Europe and China are trying to establish these standards. The developers at WiTricity see themselves soon reaching their goal in this respect. In the USA, the company already operates larger test fleets and is thinking of a timely market launch.

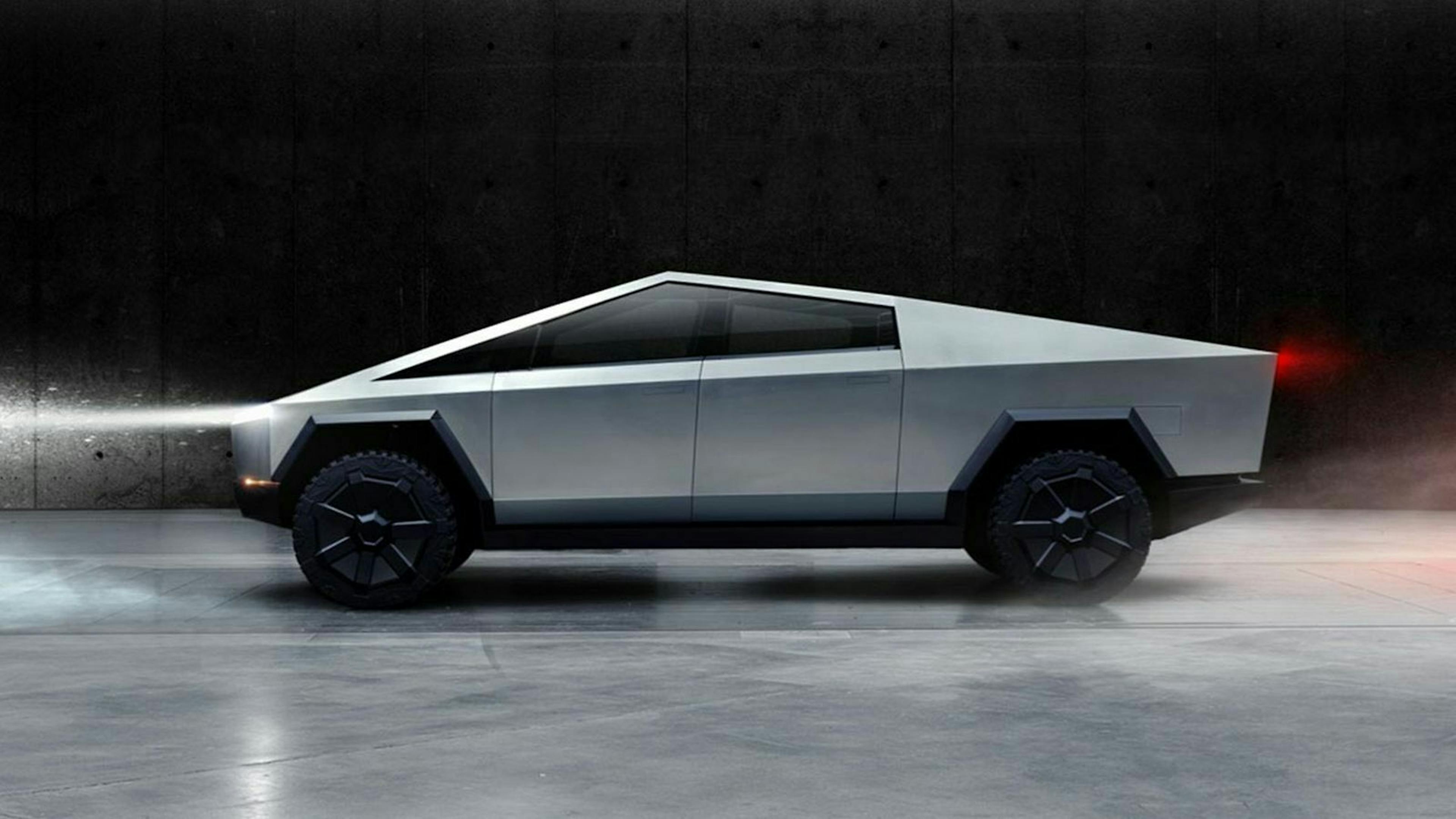

Tesla buys know-how in inductive charging

A piece of news about inductive charging is likely to further accelerate the market launch: Tesla has acquired a specialist company that has been developing and selling inductive charging systems for driverless transport systems and industrial trucks for a long time – Wiferion. The company, based in Freiburg, Baden, was founded in 2016 and, according to the commercial register entry, already operates as Tesla Engineering Germany GmbH. Tesla is likely to pursue two intentions with the purchase. On the one hand, Wiferion's developments can be used to bring the power supply of the factory's own conveyor vehicles up to date, but above all, the car models can be equipped with the customer-friendly charging system.

To do this, Tesla must succeed in positioning the cars automatically and precisely above the floor plate of the inductive charging system. This is because this is necessary so that the coils in the car and in the floor system can react to each other. Cameras or ultrasonic sensors could be used for positioning. However, Tesla has omitted both from its models. So it remains to be seen how Tesla intends to achieve the necessary high parking accuracy. Audi, BMW, Mercedes and Porsche – or in short: the competition whose cars are equipped with corresponding sensors – have a theoretical advantage here.

Theoretically, because the interest in inductive charging technology among most car manufacturers – not only those mentioned – is very limited. One of the points of criticism (in addition to the standardization, which has not yet been completed) is the limited charging power: According to current knowledge, a maximum of 22 kW can be transmitted inductively to the car, which is not enough for fast charging. If more electricity is to flow, cooling must be active and thus costly. This costs money and space and makes another alternative charging option interesting.

Alternative charging options: Inductive charging

Advantages of inductive charging

-

Very high level of comfort (no handling with cables, no need to forget to charge)

-

Bidirectional charging possible at any time (because it does not rely on plugged-in cables)

-

No wearing parts on the vehicle (no charging socket, charging cable)

-

Minimal space requirement in public spaces

Disadvantages of inductive charging

- Standardization needed (currently not yet completed)

- Exact parking required

- Critical for metallic objects between primary and secondary coil

- Charging efficiency (currently maximum 92%) gerongfüging worse than charging with cable

- for charging capacities above 22 kW, active cooling is necessary

Conductive charging – with an electric conductor, but fully automatic

In conductive power transmission, charging capacities well above 100 kW are also possible. After all, as with the cable, an electrical conductor is used here, which can transmit very high currents if it is appropriately dimensioned. However, the structure is fundamentally different from the conventional charging infrastructure. With wired charging, space is needed to set up the columns. There is far too little of this in city centres. If the urgently needed charging option reduces the size of the sidewalk or even poses a serious obstacle for pedestrians, wheelchair users or prams, acceptance is quickly gone. The floor units of conductive systems, on the other hand, can be sunk flush into the ground, as is the case with inductive systems – they are not visually significant, nor do columns or cables interfere and take up space or form tripping hazards.

The conductive systems Easelink and Volterio are expected to be almost ready for series production. Supplier Continental is committed to Volterio and states that the charging option will go into series production in 2025. Volterio's system includes a robotic arm mounted on the floor, while in the car the counterpart is mounted in the form of a bushing. It establishes the electrical contact, provided that the car is parked reasonably well above the floor plate. The system can compensate for deviations of up to 40 centimetres. Easelink goes the opposite way. Here, the loading arm is mounted under the car, while the charging plate is mounted on the ground. The system, called "Matrix Charging", is already being tested in Austria, and a taxi fleet of 60 vehicles is using it. From 2025, only e-vehicles will be newly registered as taxis in Austria. Conductive charging options at the usual taxi waiting stations would end any discussion about too short an electric range.

These systems are not quite as robust as charging via the air gap. They are more susceptible to dirt, mechanical components on the car or in the floor plate can wear out, and even here standards are still missing. But Easelink is working to establish "Matrix Charging" as an international standard. There is already a price. The components are expected to cost around 2,500 euros and another 400 euros for installation on the car.

Robotaxes are not economical without automatic loading systems

Large quantities are to be expected even if private customers do not initially rely on the technology. Inductive and conductive charging are ideal for robotic taxis: they lack the driver who can connect the battery of the passenger transporter to the mains by cable. In this case, automatic systems are the ideal solution. In any case, the robotaxi has the expensive sensors for exact positioning above the floor plate. The surcharge for automatic charging systems is not a big issue, as they help fleet operators avoid personnel costs and thus allow attractive tariffs for the use of an autonomous taxi in the future.

Science fiction because robotaxis will not be on the road for years? No, the present. In the USA, they are already in use nationwide in San Francisco and Phoenix. Waymo reports that more than 10,000 autonomous taxi rides are already taking place per week and that the service will soon be expanded to Los Angeles. The General Motors subsidiary Cruise offers the robotaxi service throughout the city of San Francisco, around the clock. That's why we dare to make a prediction here: Once the comfort-loving Americans get used to the automatic charging systems, they will say goodbye to the cable in the frunk of their electric cars once and for all.

Alternative charging options: Conductive charging

Advantages of conductive charging

-

High level of comfort (no cable handling, no need to forget to charge)

-

Large charging capacity possible

-

High efficiency

-

Bidirectional charging possible (because it does not rely on manually plugged in cables)

-

Minimal space requirement in public spaces

Disadvantages of conductive charging

- Very precise parking required

- Sensitive to dirt, critical for objects between the floor element and the vehicle counterpart

- mechanical components can wear out

- additional weight in the vehicle

- Cost overrun